Chevrolet recently debuted the new Corvette Z06 GT3.R racecar, a year before it makes its competition debut at the 2024 Rolex 24 At Daytona.

Making its public debut at Daytona International Speedway ahead of the Rolex 24, the Corvette Z06 GT3.R is Chevrolet’s first racecar that fully meets FIA technical regulations for GT3 cars.

Design and development of the mid-engine Z06 GT3.R is a collaboration between GM’s Competition Motorsports Engineering division and Pratt Miller Engineering. With an eye specifically toward customer racing, the Z06 GT3.R will be eligible for multiple championships in North America and around the world with a high level of parts and technical support available for its customers.

The Corvette Z06 GT3.R will race for the first time as part of the GT Daytona (GTD) PRO category at the 2024 Rolex 24 At Daytona to open next year’s IMSA WeatherTech SportsCar Championship.

“The Corvette Z06 GT3.R breaks new ground for Chevrolet and the Corvette Racing program,” said Mark Stielow, director, GM Motorsports Engineering Competition. “This customer-focused racecar leverages learnings from throughout Corvette Racing’s lengthy and successful history, plus the expertise of our Corvette production design, engineering and powertrain teams.”

Track and street

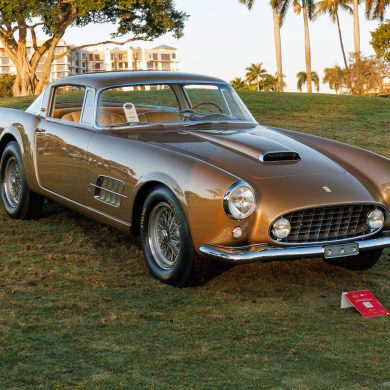

The Z06 GT3.R is a landmark racing vehicle for Chevrolet. Based on the highly acclaimed mid-engine Chevrolet Corvette Z06 supercar, this new race car takes the level of technology transfer between racing and production to a new level with more shared components and features than ever before.

“Corvette Racing has been an important influence on the design of Corvette production cars for 25 years,” said Tadge Juechter, executive chief engineer, Corvette. “Corvette production and racing teams worked together closely in development to maximize the benefits of a mid-engine design, sharing lessons learned that set both programs up for all-out performance on the track.”

The Z06 GT3.R begins its life as an aluminum chassis frame from Chevrolet’s Bowling Green Assembly plant in Kentucky[i]. The frame provides a lightweight yet strong and durable underpinning for both Z06 and Z06 GT3.R. Once in Michigan at Pratt Miller, a purpose-built steel roll cage is welded onto a base plate, which is secured to the chassis.

A double-wishbone suspension at the front and rear promotes a higher level of adjustability and fitment of racing-specific tire sizes. This is the same front and rear suspension configuration as on the Z06 production vehicle.

The motorsports engineering team added race springs and dampers, competition-specific rotors, calipers and pads. The Z06 GT3.R rides on 18-inch front and rear wheels — the same as on the C8.R.

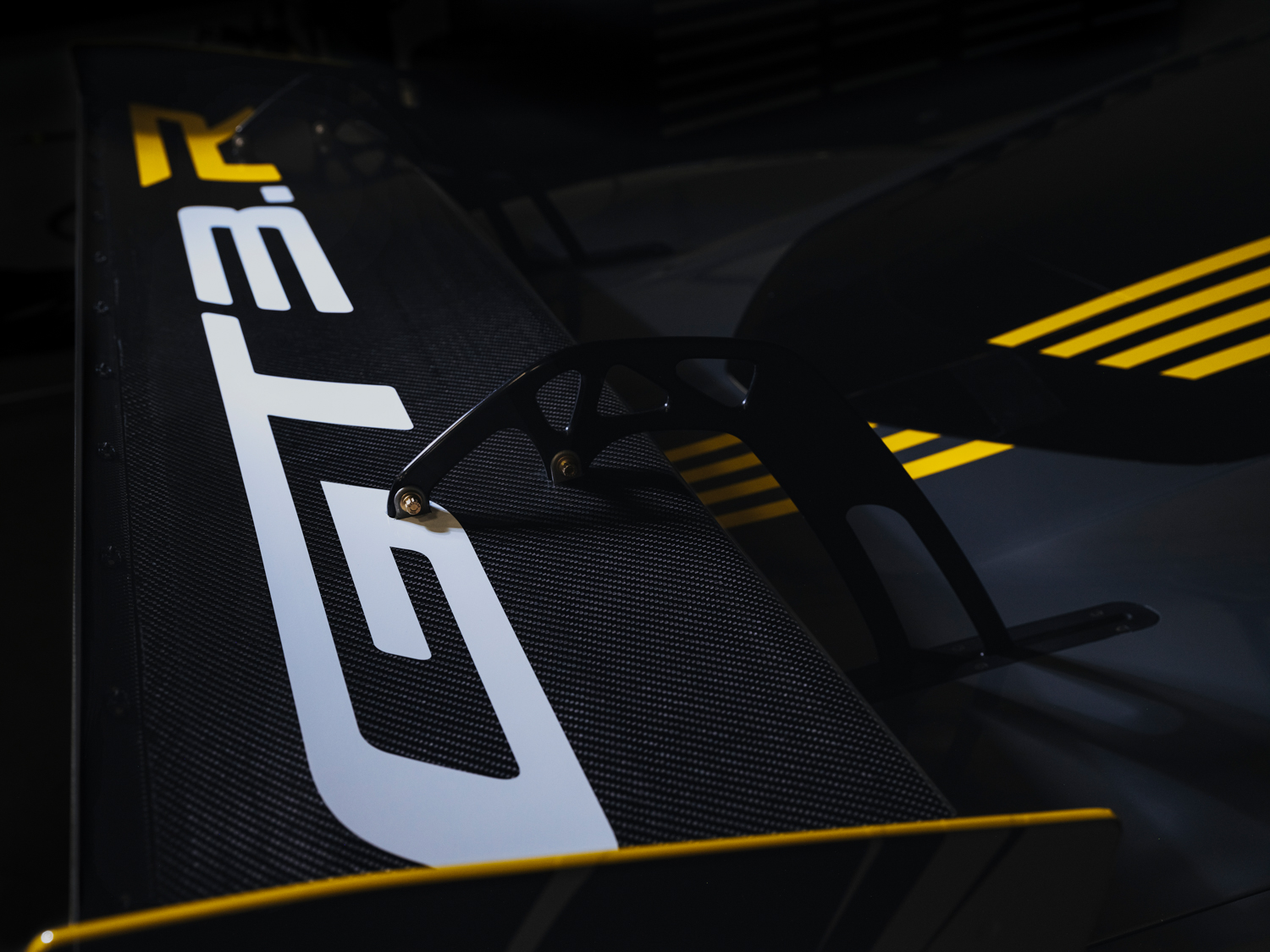

Advanced aerodynamic strategies also link the road-going Corvette and its GT3 counterpart. Motorsports engineers worked with the GM Design Studio to develop an aero package specific to the Z06 GT3.R to optimize levels of downforce, stability, drag reduction and cooling.

The goal was to design a GT3-spec Corvette that is suitable across different tire specifications, balance-of-performance settings and other customer preferences while not sacrificing performance or drivability on a variety of tracks and racing surfaces.

In order to enhance performance of the Z06 and Z06 GT3.R, each uses similar carbon fiber splitters which provide optimal downforce at the front of the vehicles. On the underside of the Z06 GT3.R, a new and purpose-designed carbon fiber diffuser routes air from the front of the car toward the rear in order to create an optimal level of overall stability.

The underbody aerodynamic devices work together in complementing the functionality of a new-for-2024 wing that aids in airflow at the rear of the Z06 GT3.R and the creation of downforce for enhanced cornering ability.

Aggressive and efficient ducting will move air to cool internal components. Intakes at the front of the Z06 GT3.R draw in air to cool the front brakes. A single, large opening on the hood — a new design philosophy from the C8.R — extracts out air after it moves over the radiator.

From the top of the windshield to the rear of the car, the surface elements of the Z06 stayed intact for the Z06 GT3.R, accentuating the tie between production and racing. Most notable are side air ducts behind the doors — directly inspired by Z06 production road car — that help to cool the engine, transaxle and rear brakes.

Corvette production power for Z06 GT3.R

The Corvette Z06 GT3.R will feature a 5.5L, flat-plane crankshaft DOHC V-8 engine derived from the production Z06. This engine began on-track development in 2019 with the initial testing of the C8.R, ahead of its use in the production Z06.

The LT6 engine for the GT3.R originates from the Performance Build Center in Bowling Green, the same line on which all production Corvette Z06 engines are built.

The 5.5L powerplant shares more than 70 percent of its parts with the production Z06 engine, including the crankshaft, connecting rods, cylinder heads, fuel injectors, coils, gaskets and a variety of other sensors.

“Racing continues to play a key role in the development of our production engines,” said Russ O’Blenes, director, Performance and Racing Propulsion Team. “There were valuable lessons learned during the C5-R through C7.R programs that aided in the development of our V-8 engines for production and racing — many dealing with efficiency, materials and light-weighting. The flow of information from Corvette Racing to production engineering and back has helped us build race and street-car engines that are fast, reliable and efficient.”

Safety structure features

Chevrolet and Pratt Miller have worked together to incorporate a number of features into the GT3.R, building on safety construction from the C8.R. The Z06 GT3 features a side-impact crash structure between the driver’s side door and roll cage. Pioneered in the C7.R, the box features an outer casing of carbon fiber and Kevlar, and is filled with an aluminum honeycomb construction.

The GT3 Corvette’s integrated steel roll cage is slightly modified from the current racing Corvette to provide easier ingress and egress.

Testing

The reveal of the Z06 GT3.R follows a two-year testing program. Virtual simulation through Chevrolet’s Driver in the Loop simulator began in early 2021.

The first on-track test of the Z06 GT3.R took place in September 2022 — which means the Z06 GT3.R will have a full year of on-track development when it gets into the hands of customers in the third quarter of 2023.

“We’re all very pleased with the results from the track testing program so far,” said Laura Wontrop Klauser, GM sports car racing program manager. “What’s even more encouraging is the correlation between simulator sessions and what we’re finding in the real-world track testing. It’s another level of validation that gives us confidence in the development process.”

Driven by success

The Z06 GT3.R is the latest in a line of championship-winning Corvette race cars that date back to the late 1990s and the introduction of Corvette Racing and the Corvette C5-R. Entering its 25th season, the program has scored 122 race victories around the world, including 113 in IMSA competition.

Those wins have led to 14 Manufacturer’s and Driver’s championships and 15 Team titles. No team in IMSA history has won more races or championships than Corvette Racing in that span.

The mid-engine C8.R — the predecessor of the Z06 GT3.R — has won 15 times around the world since its on-track debut in 2020. The 2023 season will be its second and last with a dual program in both the WeatherTech Championship and the FIA WEC. The latter will move from the current GTE regulations to the global GT3 platform beginning in 2024.

Customer support and options

Chevrolet and Corvette Racing is establishing a complete customer support program that will be available to teams running the Z06 GT3.R in North America and elsewhere around the world.

An at-track parts truck will be a fixture at North American race events starting in 2024 with expansion to overseas support ramping up in the first two years of the Z06 GT3.R program.

Corvette Racing will carry full spares packages of bodywork and internal components for its customer teams in supported championships. On the technical side, engineers will assist teams with items such as pre-race documentation, including chassis setup and data sharing plus post-event documentation, data analysis, and relative comparisons.

Full engineering, race strategy and other items also are incremental support options for Corvette Z06 GT3.R customer teams.

Customer integration doesn’t stop at the racetrack. Corvette Racing and GM Motorsports engineers will be available for remote engineering and operations support,

“Supporting our customers is an area where we are putting in a lot of time and effort,” said Christie Bagne, GM assistant sports car racing program manager. “With this being our first customer GT3 offering, we have had meetings with many prospective customers to learn from their previous experiences, find what is important to them from a support standpoint and come up with a program that meets their expectations.”

The 2024 championships

For 2024, Chevrolet and Corvette Racing will continue targeting key sports car racing championships with North American and global entries.

The IMSA WeatherTech SportsCar Championship will see up to four Corvette Z06 GT3.R entries with a mix of GTD PRO and GTD teams starting with the 2024 Rolex 24.

Two Corvette chassis will be bound for FIA WEC in hopes of a double entry in the yet-to-be-named GT category, which would include the 24 Hours of Le Mans.

Chevrolet Motorsports will also be evaluating opportunities to be represented in SRO Motorsports including SRO America and the Intercontinental GT Challenge.

Specific team announcements including drivers will be announced at a later date.

“This has been an intense but very rewarding process,” Klauser said. “From the time we announced a Corvette GT3 car, I’ve received more inquiries than I can count. It’s a testament to a known product like Corvette, the minds behind design, development and build, and the quarter-century success of Corvette Racing.”