World debut

The highly anticipated global debut of the first new Speed Six in 93 years is set to take place at this year’s Goodwood Festival of Speed. Revered as one of the most significant Bentley racing cars in history, the Speed Six has enjoyed unparalleled success. The latest iteration, referred to as Car Zero, will undergo a comprehensive development program involving real-world durability and track-based testing before being retained by Bentley, as all 12 customer cars have already been sold.

Distinguishing itself from mere replicas, a continuation car faithfully follows the original car’s design and production processes that serve as its inspiration. The Speed Six is the second pre-war Continuation Series crafted by Mulliner, Bentley’s bespoke and coachbuilding division, following the Blower Continuation Series, which was the first of its kind.

Meticulous research has been undertaken to ensure the accuracy and authenticity of the Speed Six, with particular emphasis placed on the specifications and setup of the original cars that participated in the 1930 24 Hours of Le Mans. The team made extensive use of original drawings, with approximately 80% of them discovered through the WO Bentley Memorial Foundation. These drawings were supplemented by the mechanic’s notes detailing the modifications made between the 1929 and 1930 races, as well as data obtained from the Bentley Heritage Collection’s 1930 Speed Six and an original 1930 Le Mans racer known as Old Number 3.

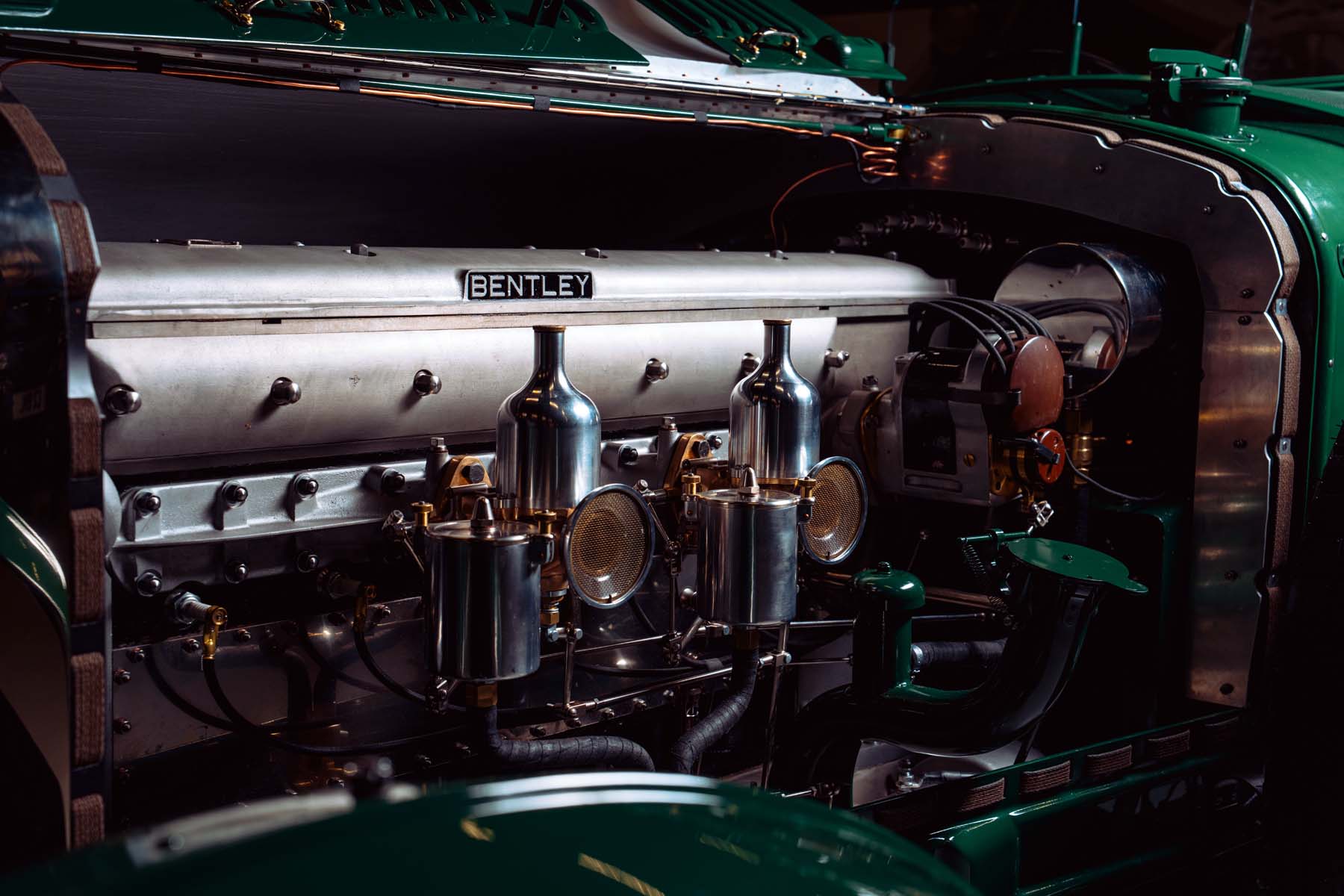

Recreating the engine

The creation of the new 6½-litre six-cylinder race-spec engine required over 600 individual new parts. Initial dyno testing has demonstrated that these engines produce a peak power output of 205 bhp, coming within a margin of 5 bhp of the documented figures for the original race-tuned engines in 1930.

The Speed Six incorporates authentic materials used in the Blower Continuation Series, particularly in its trimmed elements. To ensure historical accuracy, the Mulliner team delved into the archives of the National Motor Museum in Beaulieu, Hampshire, and identified five period Parsons exterior paints. Car Zero, representing the Speed Six, showcases the Parsons Napier Green finish with a Tan leather interior.

Preserving the past

Over the past ten months, a team of exceptionally skilled Mulliner artisans and specialists has meticulously crafted Speed Six Car Zero. As was the case with the Blower Continuation Series, the Speed Six project aims to preserve and develop modern and traditional coachbuilding skills. The collaboration between experienced craftspeople and younger artisans ensures the transfer of knowledge and expertise. The completed car is a masterpiece, entirely built and trimmed in the Mulliner workshop at Bentley’s Dream Factory in Crewe.

Over the next six months, customers will have the opportunity to discuss their specific requirements in personal commissioning sessions. To guarantee the utmost comfort for each customer, a personalized fitting service will be offered using the second development car known as Speed Six Factory Works.

A Historical Overview of the Speed Six

The Speed Six emerged as the most successful racing Bentley, boasting enhanced performance based on the 6½ Litre model. It achieved victory at the prestigious 24 Hours of Le Mans in both 1929 and 1930, thanks to the remarkable driving skills of Woolf Barnato, Sir Henry ‘Tim’ Birkin, and Glen Kidston.

W.O. Bentley’s approach to increasing power involved expanding engine capacity rather than relying on supercharging, which was championed by Tim Birkin. Consequently, he developed a larger engine to succeed the 4½-litre model. With a bore of 100 mm and a stroke of 140 mm, the new straight-six engine possessed a displacement of nearly 6.6 liters. In its standard configuration, equipped with a single Smiths five-jet carburetor, twin magnetos, and a compression ratio of 4.4:1, the 6½ Litre delivered 147 bhp at 3500 rpm. Bentley manufactured a total of 362 units at their Cricklewood factory in North London, utilizing various chassis lengths to accommodate different body styles based on individual customer preferences.

Introduced in 1928, the Speed Six chassis represented a more sports-oriented version of the 6½ Litre. The engine underwent modifications to unleash more power, incorporating twin SU carburetors, a higher compression ratio, and a high-performance camshaft, resulting in an output of 180 bhp. Customers could choose between three different wheelbases for the Speed Six chassis: 138 inches (3,505 mm), 140.5 inches (3,569 mm), and 152.5 inches (3,874 mm), with the shorter option being the most popular. Between 1928 and 1930, Bentley produced 182 Speed Six models, while the factory race cars were built on a 134-inch (11’2″) chassis frame.

The racing variant of the Speed Six featured further engine enhancements, featuring a higher compression ratio of 6.1:1 and producing 200 bhp. Its triumphs at Le Mans in 1929 and 1930 cemented the Speed Six’s place in Bentley’s illustrious history. In 1929, driven by Woolf Barnato and Sir Henry ‘Tim’ Birkin, a Speed Six led from the first lap to the checkered flag, with three other Bentleys following suit. Birkin set a new lap record of 7:21, slashing 46 seconds off the previous best, with an average speed of 83 mph. Moreover, the Speed Six covered a distance of 2,844 km, establishing another record. Such a dominant performance by a single manufacturer was unmatched at Le Mans for nearly three decades.

Real-Life Endurance

Speed Six Car Zero, showcased at the Goodwood Festival of Speed, incorporates additional instrumentation that will not be present in customer cars. These additions are aimed at supporting the validation process and collecting diverse sets of data over the next six months.

With the completion of Car Zero’s construction, a real-world durability testing program will commence. This program aims to simulate the equivalent of 35,000 kilometers of real-world driving, combining 8,000 kilometers of track driving. Gradually increasing intervals of duration and speed will assess functionality and durability under the most demanding conditions, instilling confidence in the forthcoming customer cars.

The production of the first customer car is scheduled to commence in October of this year, with the series of 12 customer cars expected to be completed by the end of 2025. Each car will undergo a 10-month construction process, tailored to meet the unique preferences of individual customers.

Original Press release courtesy of Bently

Enjoy this video from CarGold on an original Bentley Speed Six.